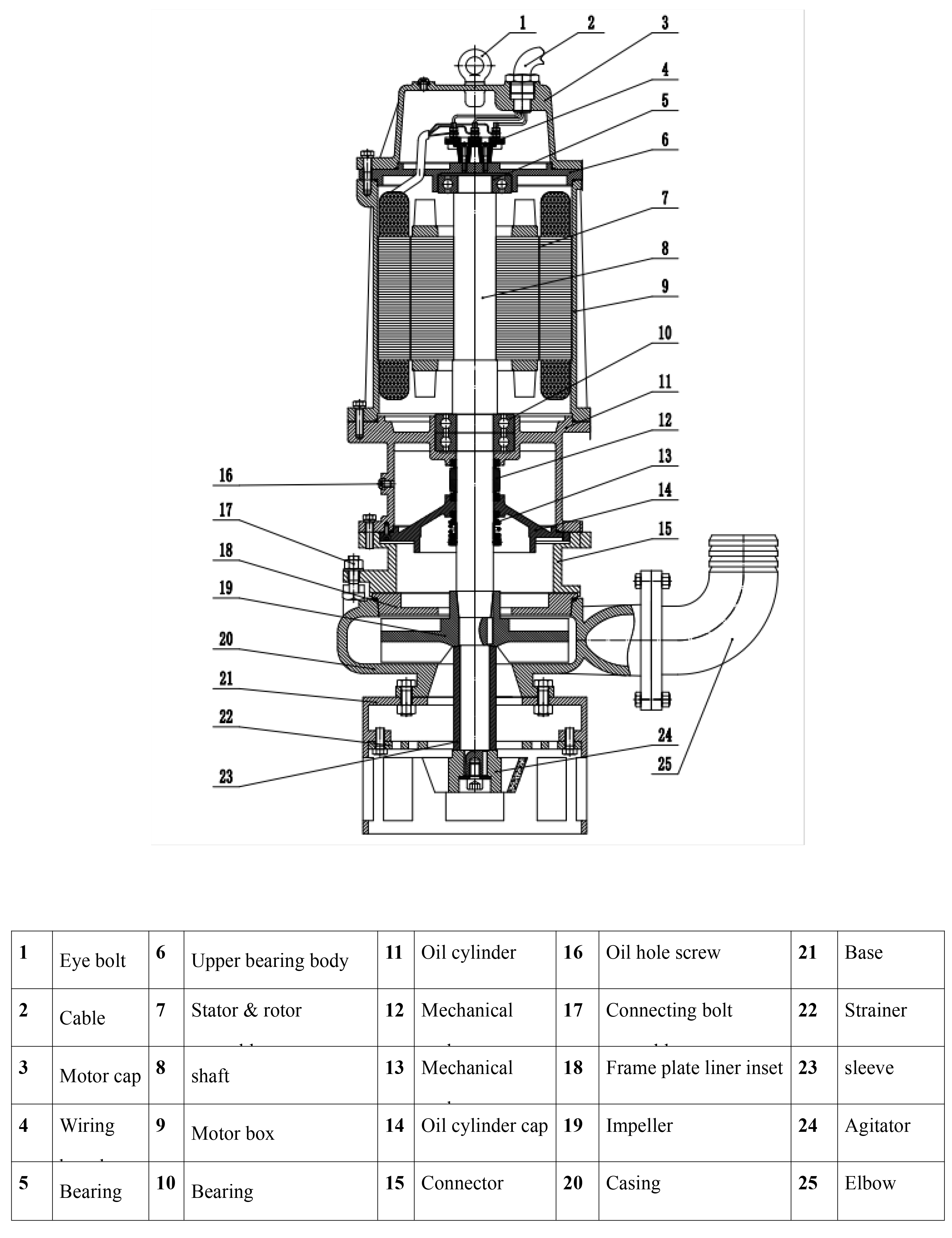

On the basis of actual test, the pump body and impeller are carefully selected and matched. The impeller of

the pump body is made of high chromium wear-resistant and corrosion-resistant material, with good non-clogging performance, high efficiency, flat power curve, not easy to overload, accurate impeller balance, small vibration and stable operation.

The stir wheel is located at the bottom of the pump, which can pump the sludge deposited at the bottom into turbulence and extract it. It integrates diving, mixing, sand blowing and sand pumping, with high sand absorption efficiency and more thorough dredging.

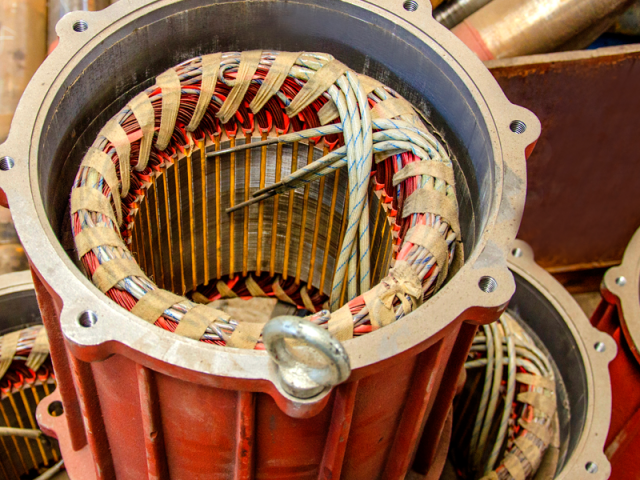

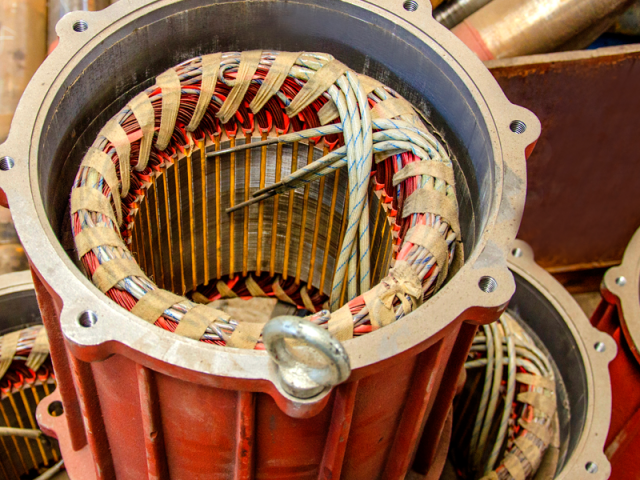

Specially designed submersible motor, IP68 protection, class F insulation allows temperature rise, under normal temperature rise conditions, the motor insulation life is long, while the diving cooling effect is good, the actual temperature rise is low, the motor insulation life is longer.

The heat of the motor is dissipated through the casing. As long as the medium submerges half of the motor stator casing, it can operate reliably and safely. The more submergence, the better the motor cooling.

The motor shaft seal adopts two independent mechanical seals in series to form two reliable sealing lines. The first one is in the medium inside the pump, and the sealing surface is pressed more tightly with the increase of medium pressure, which effectively prevents water from entering the oil chamber. The second one is in the oil chamber, which prevents oil from entering the motor. If the first one fails (its working conditions are worse than the second one), the second one can still prevent oil from entering the motor. The bellows type mechanical seal and the innovative structural cavity further improve the reliability of the shaft seal. Under normal use, the trouble free operation time is more than 8000h.

The oil chamber is a barrier to prevent the medium from entering the motor from the pump shaft to prevent the medium from penetrating into the electrode. If the first mechanical seal leaks, the buffer medium in the oil chamber cannot directly enter the motor. At the same time, the friction surfaces of two independent mechanical seals are lubricated and cooled to make the mechanical seal work more reliable. Besides, it can also take away the heat of the lower bearing and some heat of the motor.

The double row angular contact bearing at the lower part has strong bearing capacity. It forms a reliable support for the motor water pump shaft with the deep groove bearing at the upper part. It has a large bearing margin for the radial, axial and other forces generated by the sewage pump when it works, so as to ensure the smooth operation and long service life of the unit.

1>> The cable is a heavy-duty rubber sheathed flexible cable with sewage resistance. The cross-section of the cable core is designed for long-term reliable operation under 40 ℃ ambient temperature and full load power of the motor. If the sewage pump works, the motor will have a longer service life under non full load power or under 40 ℃ ambient temperature.

2>> There is a seal between the cable rubber sleeve and the motor gland to prevent the medium from seeping into the inner cavity of the motor from the interface between the cable and the motor cover.

3>>There is rubber vulcanization between the cable sleeve and the core. Once the rubber sleeve is damaged, it can still effectively prevent the medium from entering the motor from the cable sleeve.

The shell of the motor is composed of shell, upper end cover, gland, etc. all parts are connected and matched with reliable static seal. Each set is inspected by strict hydraulic test to ensure no leakage.

1>> Oil-water probe: it is installed in the oil chamber to detect the leakage of the first mechanical seal(medium). When the leakage medium reaches a certain proportion in the oil chamber, it will give an alarm.

2>> Float switch: it is installed in the motor cavity to detect the leakage of the second mechanical seal. When oil (oil-water mixture) enters the motor, the float switch will give an alarm and stop the pump.

3>> Thermal element: it is installed in the stator winding of the motor. If the motor is overloaded for a long time and the temperature of the motor winding (or other reasons for the motor winding heating) reaches a certain value, it will give an alarm and stop the pump.

The supporting special electric control cabinet can process various signals in the pump, realize the functions of control, protection, sound and light alarm, and various automatic control of single pump and multi pump.When users provide their own electric control cabinet, they should contact the professional team of electric control cabinet of our company to guide users to install protection controllers in their own electric control cabinet.

Forced cooling system. The shell of the motor is equipped with a metal sleeve to introduce the cooling water circulation to realize the forced cooling.

The actual part of the curve on the performance chart represents the recommended use range of the pump. If the flow of the pump exceeds the flow limit on the right, the shaft power will exceed the rated power of the motor, When the medium temperature is high or the motor can not be fully cooled, the motor can not work for a long time; if the flow is less than the left flow limit, the shaft power of the pump is far lower than the rated power of the motor, and the efficiency of the unit is very low, so it is not economical to use the pump under this condition.