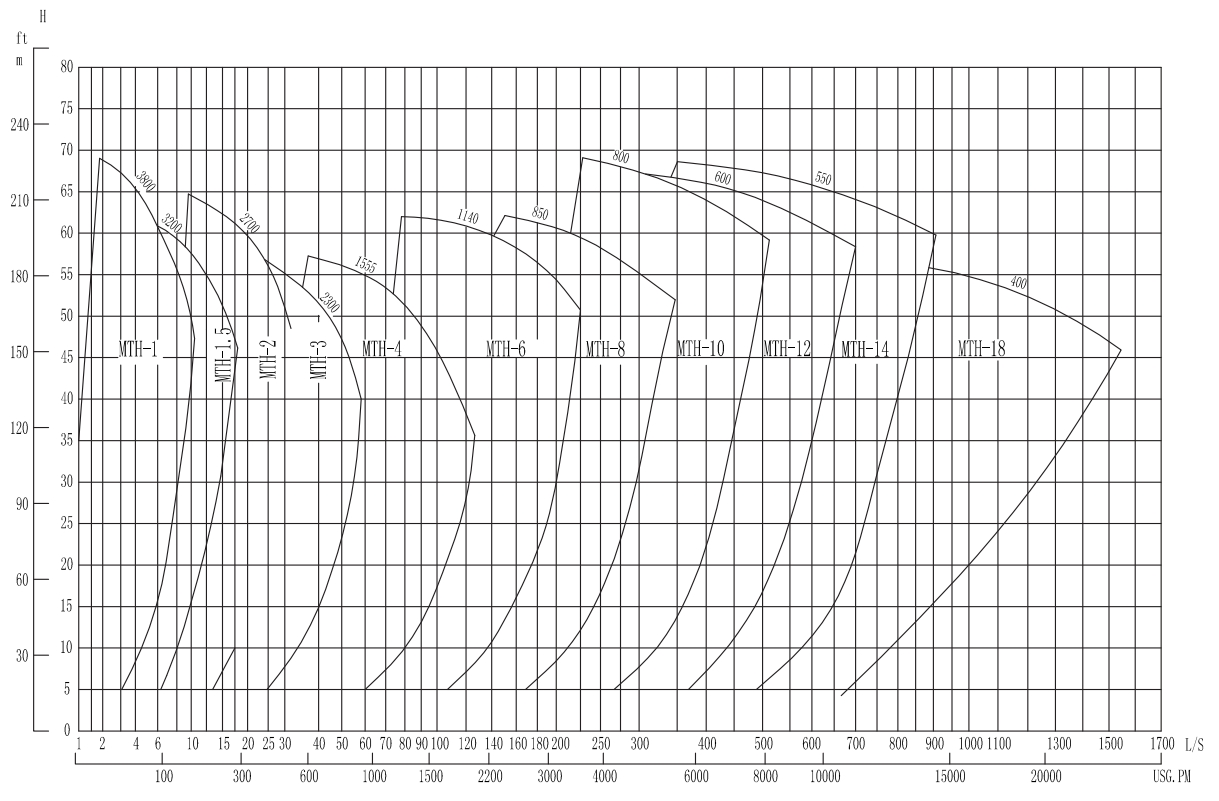

(only reference for intial model selection)

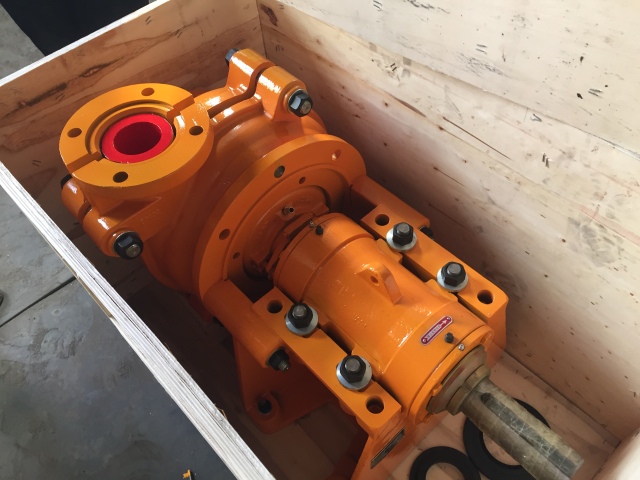

M(R)TH-4D

M: Metal Liner

R: Rubber Liner

T: Ruite Pump

H: Series

4: Discharge size in inch

D: Frame type

|

Model |

Max.Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q ( m3/h) |

Head H ( m) |

Speed n (rpm) |

Eff.η (%) |

NPSH (m) |

|||

|

TH-1B |

15 |

M |

M |

12.6~28.8 |

6~68 |

1200~3800 |

40 |

2~4 |

5 |

|

RU |

RU |

10.8~25.2 |

7~52 |

1400~3400 |

35 |

3 |

|||

|

THH-1C |

30 |

M |

M |

16.2~34.2 |

25~92 |

1400~2200 |

20 |

1~5.5 |

5 |

|

TH-1.5B |

15 |

M |

M |

32.4~72 |

6~58 |

1200~3200 |

45 |

3.5~8 |

5 |

|

RU |

RU |

25.2~54 |

5.5~41 |

1000~2600 |

50 |

2.5~5 |

|||

|

TH-2C |

30 |

M |

M |

39.6~86.4 |

12~64 |

1300~2700 |

55 |

4~6 |

5 |

|

RU |

RU |

36~75.6 |

13~39 |

1300~2100 |

2~4 |

||||

|

THH-2D |

60 |

M |

M |

68.4~126.8 |

25~87 |

850~11400 |

47 |

3~7.5 |

5 |

|

TH-3C |

30 |

M |

M |

86.4~198 |

9~52 |

1000~2200 |

71 |

4~6 |

5 |

|

RU |

RU |

79.2~180 |

5~34.5 |

800~1800 |

59 |

3~5 |

5 |

||

|

TH-3D |

60 |

M |

M |

97.2~198 |

9~53 |

1000~2200 |

71 |

4~6 |

5 |

|

RU |

RU |

79.2~180 |

5~34.5 |

800~1800 |

59 |

3~5 |

5 |

||

|

THH-3E |

120 |

M |

M |

126~252 |

12~97 |

600~1400 |

50 |

2~5 |

5 |

|

TH-4D |

60 |

M |

M |

162~360 |

12~56 |

800~1550 |

65 |

5~8 |

5 |

|

RU |

RU |

144~324 |

12~45 |

800~1350 |

65 |

3~5 |

5 |

||

|

TH-4E |

120 |

M |

M |

162~360 |

12~56 |

800~1550 |

65 |

5~8 |

5 |

|

RU |

RU |

144~324 |

12~45 |

800~1350 |

65 |

3~5 |

5 |

||

|

THH-4S |

560 |

M |

M |

324~720 |

30~118 |

600~1000 |

64 |

3~8 |

5 |

|

TH-6E |

120 |

M |

M |

360~828 |

10~61 |

500~1140 |

72 |

2~9 |

5 |

|

RU |

RU |

324~720 |

7~49 |

400~1000 |

65 |

5~10 |

5 |

||

|

TH-6R |

300 |

M |

M |

360~828 |

10~61 |

500~1140 |

72 |

2~9 |

5 |

|

RU |

RU |

324~720 |

7~49 |

400~1000 |

65 |

5~10 |

5 |

||

|

TH-8ST |

560 |

M |

M |

612~1368 |

11~61 |

400~850 |

71 |

4~10 |

5 |

|

RU |

RU |

540~1188 |

12~50 |

400~750 |

75 |

4~12 |

|||

|

TM-8E |

120 |

M |

M |

666~1440 |

14~60 |

600~1100 |

73 |

4~10 |

5 |

|

RU |

RU |

540~1188 |

10~42 |

500~900 |

79 |

5~9 |

5 |

||

|

TH-10ST |

560 |

M |

M |

936~1980 |

7~68 |

300~800 |

82 |

6 |

5 |

|

RU |

RU |

720~1620 |

7~45 |

300~650 |

80 |

2.5~7.5 |

|||

|

TH-12ST |

560 |

M |

M |

1260~2772 |

13~63 |

300~600 |

77 |

3~10 |

5 |

|

RU |

RU |

1152~2520 |

13~44 |

300~500 |

79 |

3~8 |

5 |

||

|

TH-14ST |

560 |

M |

M |

1368~3060 |

11~63 |

250~550 |

79 |

4~10 |

5 |

|

TH-14TU |

1200 |

||||||||

|

TH-16ST |

560 |

M |

M |

2160~5040 |

8~66 |

200~500 |

80 |

4.5~9 |

5 |

|

TH-16TU |

1200 |

||||||||

|

TH-18TU |

1200 |

M |

M |

2520~5400 |

13~57 |

200~400 |

85 |

5~10 |

5 |

| Pump Mainly Parts & Material List | |||||

| NO | Part | Material | NO | Part | Material |

| 1 | Shaft | High tense steel | 12 | Volute | 27% Chrome alloy |

| - | Shaft sleeve | 3Cr13 | 13 | Discharge joint ring | Natural rubber |

| 2 | Clamp bolts | Zinc plated steel | 14 | Volute liner seal | Natural rubber |

| 3 | Base | Ductile iron | 15 | Intake joint ring | Natural rubber |

| 4 | bolts,studs | Zinc plated steel | 16 | Expeller | 27% Chrome alloy |

| - | Bearing body | Cast iron | 17 | Frame plate liner insert | 27% Chrome alloy |

| 5 | Gland/Split gland | Cast iron | 18 | Throatbush | 27% Chrome alloy |

| 6 | Frame plate | Ductile iron | 19 | Cover plate | Ductile iron |

| 7 | Expeller ring | 27% Chrome alloy | 20 | Cotter | Cast iron |

| 8 | Expeller ring seal | Natural rubber | - | End cover | Color zinc plated |

| 9 | Volute liner seal | Natural rubber | - | Labyrinth cover | Color zinc plated |

| 10 | Impeller | 27% Chrome alloy | - | Lantern ring | 1Cr18Ni9TI |

| 11 | Cover plate bolt | Zinc plated steel | - | Bearing | Top brand |

TH Slurry Pumps Shaft Seal Arrangement:

• Packing Seal is a general shaft seal.It applys to various pumping conditions, PTFE and Graphite materials of Packing can be used in high corrosive slurries or high temperature conditions.Using ceramic shaft sleeve,For high abrasion conditions, The ceramic shaft sleeve is available.

|

|

No. |

Part name |

Materials |

|

1 |

Stuffing box |

KmTBCr27 |

|

|

2 |

Lantern restrictor |

1Cr8Ni9Ti |

|

|

3 |

Packing |

PTFE |

|

|

4 |

Gland assembly |

HT250 |

|

|

5 |

Shaft sleeve |

KS81 |

• Expeller Seal is an impeller force of reversed centrifugal force, preventing slurry leakage. Expeller seal can be used on the single-stage pump when the positive pressure of pump inlet is no more than 10% of pump outlet pressure or on the first-stage pump in the pump series.

|

|

No. |

Part name |

Materials |

|

1 |

Expeller ring |

KmTBCr27 |

|

|

2 |

Expeller |

KmTBCr27 |

|

|

3 |

Packing |

PTFE |

|

|

4 |

Neck ring |

1Cr8Ni9Ti |

|

|

5 |

Lantern ring |

1Cr8Ni9Ti |

|

|

6 |

Gland assembly |

HT250 |

|

|

7 |

Oil cup |

Q235 |

• Mechanical Seal is advanced sealing technique without sealing leakage, The advantages are integrating construction, convenient installation & replacement, The design of mechanical seal and seal box is suitable for liquid flow condition,So it has high abrasion and vibration resistance, Mechanical seal can be used in various severe conditions.

|

|

No. |

Part name |

Materials |

|

1 |

Static ring assembly |

SS316 |

|

|

2 |

Rotating ring assembly |

SS316 |

|

|

|

| Advanced bearing assembly using grease lubrication The diameter of the pump shaft is large and the heavy load design is a simple structure with small size and less space. The use of grease lubrication, no oil leakage, the minimum maintenance, the rotor is easy to adjust, can be used in series. |

Bearing assembil using oil lubrication with houizontally split casing The diameter of the pump shaft is large, the rigidity is good, the cantilever is short, and it will not bend and vibration under the bad working condition. The metric bearing is lubricated by thin oil, and the bearing is directly installed in the horizontal middle open bracket. The check and adjustment is convenient, and the water cooling system is equipped to improve the working condition of the bearing, so that the bearing can run at a lower temperature and greatly improve the service life of the bearing. |

Innovative cylindrical bearing assembly using oil lubrication The pump shaft has a large diameter and a heavy-duty design of the simple structure. The metric bearing is made of thin oil lubricating oil and can be used in series. The structure has the advantages of small volume and high reliability. |